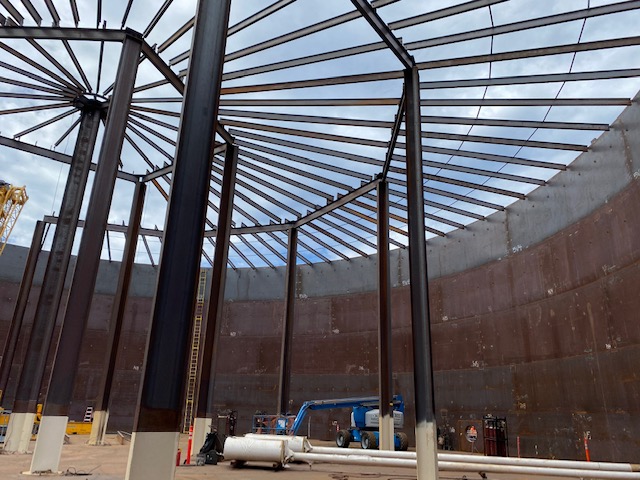

ArcelorMittal Dofasco – Steel Mill Construction – 2015

Matrix NAC completed the mechanical and electrical work for the construction of a new steel mill. The project included extensive millwrighting, piping, electrical, and some boilermaker work.

The construction approach divided the project into three main areas: entry end, center zone, and exit end.

• Entry end: hot bridle, pay off reels, welder, looper (accumulator), structure, and furnace sections

• Center zone: zinc pot, after pot cooling (APC) tower that houses a movable soaking furnace, 1st cooling, top rolls, 2nd cooling, dryer, and quench tank

• Exit end: bridle roll unit, temper mill, tension leveler, structure, looper (accumulator), belt wrapper, and exit coil car

There were also three additional areas peripheral to the process line: main utility rack, batch anneal coil movement bridge, and cooling tower pump house.

The main utility rack was constructed from the entry end through the exit end. This 700ft rack required extensive scaffolding throughout, to allow access for erection, piping, electrical, and insulation. Matrix was able to simultaneously install cable and piping to the equipment for the final setting.

Mobilized in 2012, this project was completed in August of 2015.

Scope of Work

- Assembly and installation of all process equipment/ancillaries

- Installation of main utility rack

- Batch anneal coil movement bridge

- Cooling tower/pump house